Forklift Signs-- Affordable Safety Solutions for Industrial Workplaces

Forklift Signs-- Affordable Safety Solutions for Industrial Workplaces

Blog Article

Forklift Safety Signs: Necessary Tips for Optimal Positioning and Presence

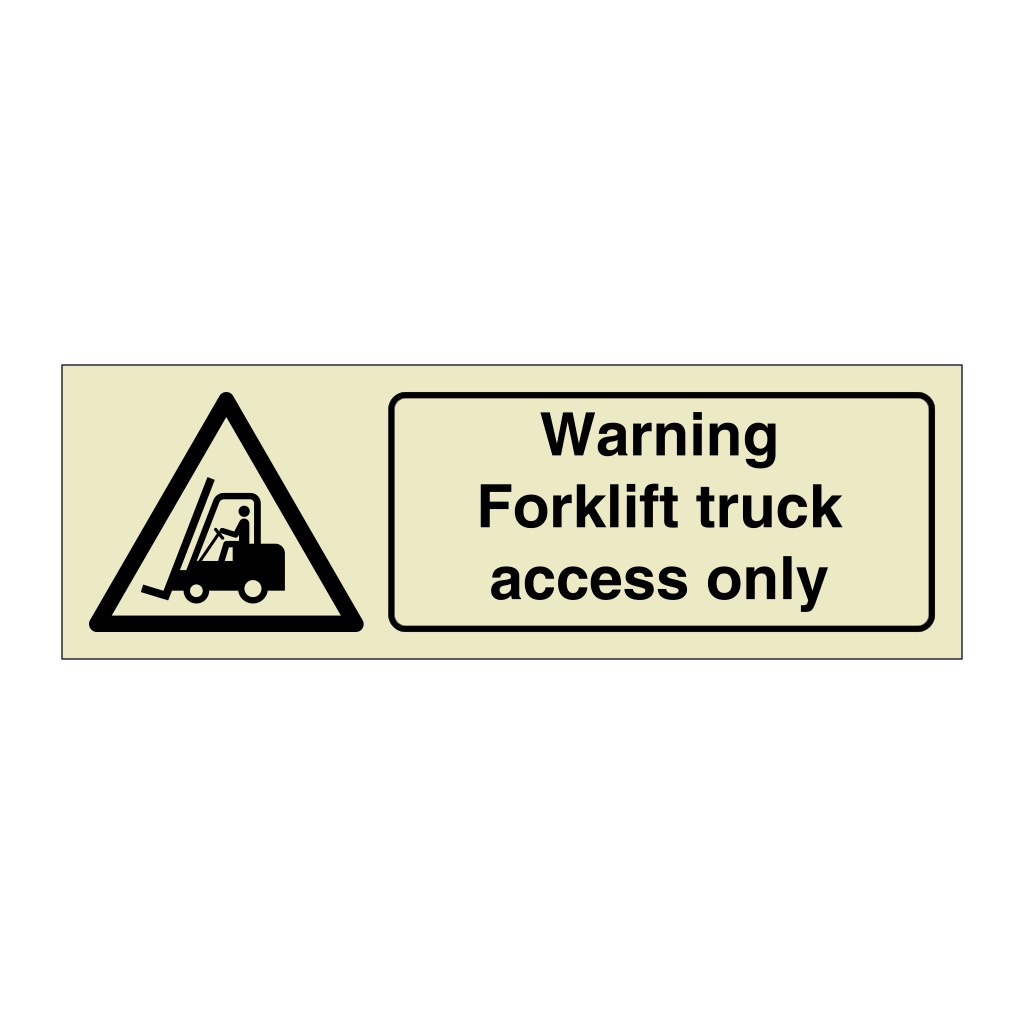

Making certain the optimum positioning and visibility of forklift security indicators is essential in keeping a safe and secure commercial setting. Placing these indicators at critical places such as entrance and departure points of packing anchors, key center junctions, and high-traffic storage areas can significantly alleviate accident risks.

Trick Locations for Safety And Security Indications

Correct placement of forklift safety indicators is crucial for preserving a safe functioning environment. Additionally, positioning signs near high-traffic storage space locations and blind areas can additionally improve presence and recognition.

Loading docks are specifically dangerous areas where forklift procedures are intensive. Indicators showing rate limits, stop points, and caution areas should be prominently displayed. Junctions within the facility are an additional critical location where collisions can happen; consequently, quit signs and right-of-way signs are essential. In pedestrian-heavy areas, indicators ought to signal both drivers and pedestrians to the visibility of forklifts, making certain every person continues to be vigilant.

Locations with high storage shelfs and unseen areas present one-of-a-kind challenges. forklift safety signs. Signage in these zones ought to caution drivers of restricted presence and motivate the use of watchmans or extra security steps. By focusing on these essential locations, companies can produce a much safer, a lot more effective workplace for all

Height and Angle Factors To Consider

When mounting forklift safety signs, taking into consideration the height and angle of positioning is crucial to make certain optimum exposure and efficiency. Appropriate height guarantees that drivers and pedestrians can quickly see the indications without obstruction.

If an indicator is implied to warn forklift drivers, it needs to be positioned straight in their area of sight, preferably perpendicular to their direction of traveling. In areas with numerous seeing angles, consider making use of double-sided signs or tilted brackets to keep presence from numerous instructions.

In addition, guaranteeing that the indicators are not obstructed by other items, machinery, or shelving systems is crucial. Clear sightlines aid prevent accidents and boost total security. By thoughtfully taking into consideration height and angle, you can dramatically improve the performance of forklift safety and security signs, therefore promoting a safer job setting.

Signage Product and Durability

Selecting the ideal product for forklift security indicators is vital for ensuring their long life and performance. In environments where forklifts run, indicators are usually subjected to severe conditions, consisting of physical impacts, chemical spills, and varying temperature levels. Selecting sturdy products like light weight aluminum, high-density polyethylene (HDPE), and polyvinyl chloride (PVC) can dramatically boost the indicators' life-span.

Aluminum is a preferred selection due to its resistance to rust and rust, making it ideal for both indoor and exterior setups. Furthermore, its lightweight nature helps with simple setup and repositioning. HDPE is another durable alternative, understood for its excellent resistance to chemicals and effect. It is particularly appropriate for settings where chemical direct exposure prevails. PVC, on the various other hand, uses an excellent balance in between longevity and cost-effectiveness, making it a common selection for lots of industrial atmospheres.

Furthermore, the printing technique made use of on these materials likewise contributes in resilience. UV-resistant inks and safety laminates help in avoiding fading and damages from sunshine and various other ecological elements. Abiding by these factors to consider ensures that forklift safety indications remain noticeable and understandable over extended periods, thus keeping a risk-free working environment.

Ensuring Indication Exposure

While picking durable products for forklift safety indicators is necessary, guaranteeing their exposure is just as vital for preserving a safe environment. Reliable exposure can be achieved through critical placement, appropriate illumination, and utilizing high-contrast colors. Signs ought to be placed at eye level and in locations where operators and pedestrians are more than likely to see them, such as at entry points, junctions, and locations with high traffic.

Proper find lighting is essential to guarantee that indicators are noticeable in all conditions. Setting up sufficient lighting in dimly lit locations or making use of reflective materials on signs can significantly improve visibility.

In addition, staying clear of aesthetic clutter around the indications is important. Way too many check in one area can overwhelm and perplex people, decreasing the performance of each sign. Clear, concise messaging and making certain indicators are devoid of obstructions such as devices or storage space products will better enhance their presence and effectiveness, adding to a more secure workplace atmosphere.

Normal Evaluation and Maintenance

Uniformity is essential to preserving the performance of forklift safety and security signs, making regular inspection and upkeep essential. To make certain these signs remain to interact essential information plainly, they must be consistently checked for deterioration, fading, or obstruction. forklift safety signs. Gradually, direct exposure to the elements and functional tasks can degrade their visibility and clarity, undermining their objective

An organized examination schedule should be established, with checks performed at normal intervals. Throughout examinations, evaluate each sign's condition, making certain text and icons stay clear and vivid. Any indicators revealing indicators of damage or fading ought to be promptly changed. Additionally, ensure that signs are not covered by equipment, supply, or various other challenges.

Verdict

Proper positioning and presence of forklift safety indicators are important in lessening workplace crashes. Positioning signs at crucial locations such as entry and departure points, facility intersections, and high-traffic storage space areas, while ensuring they official statement are mounted at eye level and tilted in the direction of oncoming traffic, enhances their effectiveness.

Report this page